- November 28, 2015

Driving productivity within service based operations is a constant challenge for management. There is always the risk for engineers to go low visibility, be it field or site based. The challenge is to identify areas of poor performance, understand the root cause of issues impacting performance and drive these out of the operation. The question is how?

Many senior managers are quick to opt for technology, believing automated scheduling tools alone will improve productivity. Others believe applying Lean principles will deliver financial benefit but become somewhat disillusioned when they don’t see the bottom line improvement they seek. So what goes wrong? Why do many Lean initiatives fail to deliver the financial benefits desired?

Through improving processes and shaving task completion times, many Lean advocates will present time savings as a financial gain and promote the success of an initiative. However, unless these improvements materialise at the bottom line via headcount reduction or increased productivity, they are simply nominal savings. In a service environment, reducing work completion times will only yield financial benefit where the spare capacity is translated into increased revenue generation, or reduced cost, which often isn’t the case.

Whilst Lean may improve processes, this will only have a positive impact at the front end if engineer behaviours are compliant with the changes and reinforced through effective management. In many of our engagements, spending time with engineers on site typically highlights workarounds and disconnects to agreed processes, causing wastage in the work stream. Supervisors need to embrace an active style of management to identify the root cause of wastage, and manage this out of the operation on a daily basis, in order to drive performance. However, commonly issues are ignored, brushed under the carpet or, more worryingly, not identified due to a lack of time spent with engineers on site. If you want to see how good an operation is (or isn’t) then look at the front end, as this will highlight many of the issues affecting performance. Lean principles will not address these issues.

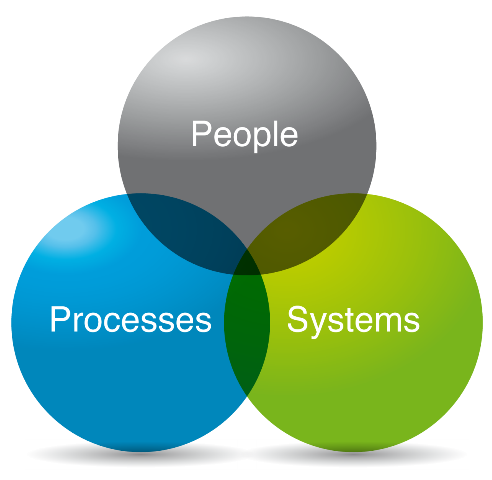

As MIT professor Deborah J Nightingale states, “The current lean paradigm is only a halfway measure for improving your enterprise in a meaningful way.” Of course Lean will go part of the way to addressing poor performance, but something else is needed to drive desired behaviours. In order to drive positive change in a sustainable manner that delivers bottom line benefit, a more holistic approach is required, one that brings together People, Process and Systems. Implementing an effective management system, that measures performance against robust operational indicators, at short intervals of control, will highlight wastage within an operation and present opportunity for improvement. Embedding an active style of supervision drives the right behaviours, thus identifying and resolving the issues causing lost time.

Consider a common situation where a contractor has been awarded a service based contract and the workforce TUPE across. Having submitted a more competitive bid than the incumbent, the contractor has to deliver the service at a lower cost and achieve year-on-year cost savings. So what will change? Six or even twelve months into the contract margin aspirations are not being met, and the pressure is on to reduce cost, but not at the expense of service levels and customer satisfaction.

In this situation the problem is far more complex than improving processes. It is not enough to simply hand out the new uniform and change the logo on the pay slips; a full transformation programme is required to embed a new way of working, demonstrate the benefits to all parties and get the support required to truly transform the way the business operates.

Lean won’t provide the operational and financial step change required. A more holistic approach is needed: Powerful new management operating systems and processes are required to support a more desired management style and drive out wastage. It’s about People, Process and Systems.